Austenitic

Providing an easy path for the most challenging applications

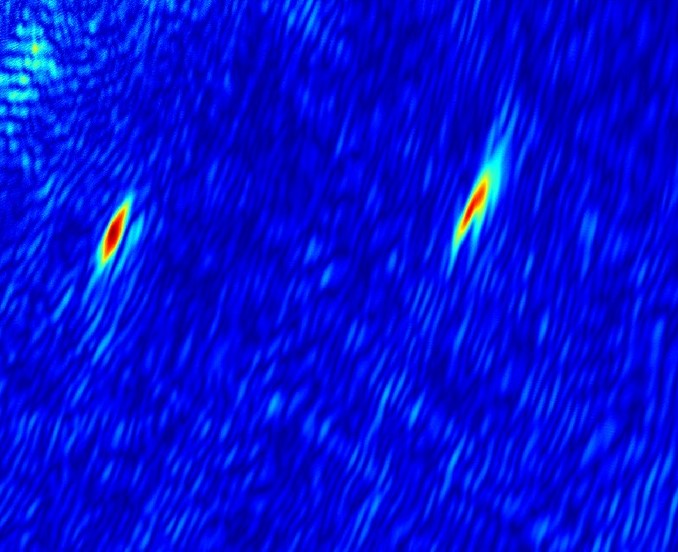

Silencing the noise

Trust in TPAC for attenuative, dispersive and large grain noise metal inspections!

Although austenitic materials are highly valued for their corrosion resistant properties, these inherent properties can also pose quite an inspection challenge. The grain structure of austenite, welded austenite especially, is generally unfavorable to the propagation of ultrasound. To help you address this inspection challenge, TPAC offers you high channel count PAUT and FMC/TFM capabilities, all in a compact and lightweight package. Whether linear, matrix, or dual arrays, we can support you in whatever configuration and whatever frequency you need.

TPAC leads the NDT industry in the development of cutting-edge Ultrasonic Testing inspection techniques. Whether multi-channel conventional, phased array, or FMC/TFM, TPAC has the technology you can trust. TPAC offers a large spectrum of scattering noise reduction algorism that goes well along with simplicity of use.